“The story of civilization is, in a sense, the story of engineering—that long and arduous struggle to make the forces of nature work for man’s good.”

– L. Sprague de Camp

When author L. Sprague de Camp was writing his science fiction and fantasy books in the 1960s and 70s, scientific understanding of human impact on the global climate was still nascent. Yet his perspective bears scrutiny today. We continue to ‘struggle’ to use nature’s resources wisely for our own benefit. Through our consumption and release of carbon into the atmosphere over generations, we are facing a struggle of our own making. But what if the solutions are the same as de Camp suggests: to engineer what nature provides for us?

For both economic reasons and imperfect-but-well-meaning environmental concerns, the design and construction industries have relied on low-cost and man-made materials for decades. Using concrete and steel, plastics and polymers, we have been designing and dwelling in communities of sleek slabs. But what if the most modern, innovative, and lower cost materials are closer to nature?

The actual costs of prioritizing lower-cost and synthetic building and construction materials may turn out to be much higher than estimated. Up-front cost savings hid the true costs—economic, environmental, and health—of high-carbon consumption.

Our engineering challenges today entail not only how to build communities, but also how to reduce carbon emissions and pull carbon from the atmosphere to allow humans to continue to inhabit the Earth. The story of our future, to extrapolate from de Camp’s observation, will be written by the engineers, designers, planners, and architects who can show the power of wood as the building material for the global good.

Nathan Jeppson

President & CEO

“Wood may be one of the world’s oldest building materials, but it is now also one of the most advanced. Building stronger markets for innovative new wood products supports sustainable forestry, helps buffer and/or reduce greenhouse gas emissions, and puts rural America at the forefront of an emerging industry.” 1

– USDA Secretary Tom Vilsack

Introduction

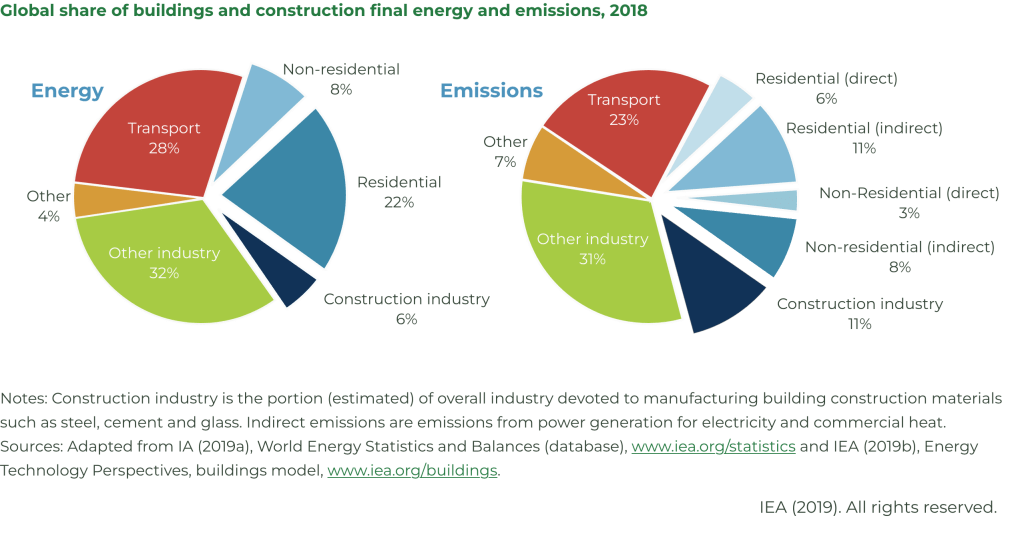

Buildings, and all related activities—construction, use, maintenance, demolition—account for 36 percent of the world’s energy usage and 39 percent of greenhouse gas (GHG) emissions. Approximately one-third of those figures come directly from the manufacturing of construction materials (International Energy Agency, 2019, p. 12). As a result, researchers urge the building and construction sector to focus efforts on reducing their carbon footprint, asserting that it should be “the primary target for GHG emissions mitigation efforts” (International Energy Agency, 2019).

Reducing GHG emissions in the building and construction sector requires a radical and deep commitment to using renewable, low-carbon resources as well as investment in innovative materials to improve existing non-renewable sources.

“Wood may be one of the world’s oldest building materials, but it is now also one of the most advanced. Building stronger markets for innovative new wood products supports sustainable forestry, helps buffer and/or reduce greenhouse gas emissions, and puts rural America at the forefront of an emerging industry.” 1

– USDA Secretary Tom Vilsack

In this white paper, we explore why wood, as a building and construction material, is the best choice to reduce global greenhouse gases and mitigate climate change for three reasons:

• Lower greenhouse gas emissions at all parts of a wood product’s life cycle

• Carbon storage in the wood product making it a net-negative choice

• Energy efficiency in both initial use and life cycle use

We’ll also make the case that hardwoods provide added sustainability and viability benefits for the future due to the:

• Long-term viability of managed hardwood forest harvesting

• Individual and community appeal of hardwood in lived spaces such as homes, schools, and workplaces

Wood is a Net-Negative Emissions Building Material

The gold standard for measuring and predicting the environmental impacts of construction projects is to conduct a thorough Life Cycle Assessment (LCA). LCAs consider all the fossil fuel emissions involved in the project from the very beginning (harvesting or generation of resources), through construction, to demolition and any reuse of materials.

This methodology is widely respected due to its scientifically rigorous and highly specific nature. Organizations such as the Consortium for Research on Renewable Industrial Materials (CORRIM) develop LCA reports, conduct independent studies, and compile case study comparisons to help provide more context. In these analyses by CORRIM and other independent organizations, wood outperforms concrete and steel on greenhouse gas emissions, energy consumption, and air pollution.

Sustainably managed and harvested forests are carbon neutral. In the forest’s lifecycle, the carbon emissions produced in the replanting, growing, and harvesting of wood are offset by the carbon that remains stored in the trees. Though the harvesting and manufacturing of wood does emit carbon dioxide, the U.S. Forest Service Office of Sustainability & Climate, following guidelines set by the International Panel of Climate Change, explains that these emissions are part of a “closed loop” because trees capture carbon from the atmosphere at a rate of approximately 48 pounds of carbon per year per tree (Ten Million Trees, 2018). (United Forest Service Office of Sustainability & Climate, p. 1).

While globally the total carbon emissions offset by forests and wood products was less than one percent in 2015, Johnston et al. (2019) notes that the total sequestration of carbon in the United States is much higher. The most recent data indicates that “since at least 1990, U.S. forests have served as a net sink rather than a net source of carbon,” offsetting approximately nine percent of U.S. carbon emissions (Environmental Protection Agency, 2018).

Energy and Emissions from Manufacturing

Carbon remains stored in wood after it is harvested and converted to products such as lumber. In fact, by dry weight, “wood is about 50 percent carbon” (Woodworks, 2011, p. 1). This means that additional emissions from processing, transportation, and any other manufacturing activities is offset by the carbon stored in the dry wood. According to the American Hardwood Export Council, wood materials are “almost always better than carbon neutral—irrespective of the transport distance involved” (Oliver, 2017, p. 14).

Understanding that wood products and the forestry industry serve as vessels for carbon storage reveals the tremendous implications for achieving sustainability goals. Building with wood does more than mitigate carbon emissions—it proactively removes carbon from the atmosphere. Due to the urgency of improving our global carbon standing, net-negative emissions are exactly what leaders and environmental authorities will begin to expect, according to forest economist Craig Johnston, Ph.D. (University of Wisconsin-Madison, 2019).

LCAs show that opting for wood in construction projects lowers the project’s carbon footprint. Researchers commonly cite CORRIM’s comparative study of homes in Minneapolis and Atlanta to show the differences in life cycle energy consumption and carbon emissions between the most common building materials in each city (wood and steel in Minneapolis, and wood and concrete in Atlanta). The results show a higher GHG emission rate and greater embodied energy for the steel and concrete homes in both cities, with the Minneapolis wood home being net negative for carbon emissions (Perez-Garcia et al., 2005, pp. 14-15).

These findings were replicated on a smaller scale in a later 2010 CORRIM study that evaluated flooring material options. Of four flooring materials (kiln-dried lumber, plywood, oriented strand board, and concrete), results show that each wood-based floor resulted in significantly lower emissions during manufacturing. And that “the carbon in the [wood] products more than offsets the emissions from processing” (Lippke, Wilson, et al., 2010, p. 8).

A 2011 study evaluating common manufacturing materials (such as steel studs or concrete slabs) found that replacing these materials with their respective wood-based alternatives reduced carbon emissions markedly: between 2 and 10 kilograms of CO2 per kilogram of wood (Lippke et al., 2011, p. 312).

These results were reinforced by the Canadian Wood Council in a 2012 study that compared 50,000-square-foot office buildings made from wood, steel, and concrete. The research indicated that wood was the top performer on measures of:

- Total energy use

- GHG emissions

- Air pollution

- Overall ecological resource impact (Woodworks, 2012, p. 2)

“The best uses of wood provide an advanced ‘carbon negative technology’ with high leverage to displace fossil emissions.”2

Bruce Lippke, Former President of CORRIM – Maureen Puettmann, Ph.D., Director of Operations for CORRIM – Elaine Oneil, Ph.D., Director of Science and Sustainability for CORRIM

Energy Efficiency in Ongoing Building Use

Beyond manufacturing, transporting, and processing, wood is also a more energy-efficient building material. Wood is far less thermally conductive than steel or concrete: “The thermal properties of wood products are 400 times better than steel and 10 times better than concrete” (Tahan, 2014). Wood is also a more naturally airtight material. More heat generated within the building stays inside (Tahan, 2014).

In a study by the APA Engineered Wood Association, three types of wall construction were used in otherwise identical multifamily buildings in three different climate zones. The three types analyzed included wood-framed, metal-framed, and concrete masonry units (CMU). By analyzing the annual energy cost, the study found that while the energy costs were similar in warmer climates, the benefits of wood become increasingly apparent in cold climates. This study’s cold climate group showed that “the wood framed walls reduce annual energy consumption by 18 percent compared to steel framing and by 10 percent compared to CMU walls” (Halverson, 2015).

Summary

Multiple LCAs and case studies consistently show that wood outperforms concrete and steel when it comes to GHG emissions, carbon storage, and energy consumption. Through continued investment and implementation of sustainable forestry best practices, wood is a reliably net-negative emissions building material.

Future Thinking with Green Building and Evidenced-Based Design

Multiple LCAs and case studies consistently show that wood outperforms concrete and steel when it comes to GHG emissions, carbon storage, and energy consumption. Through continued investment and implementation of sustainable forestry best practices, wood is a reliably net-negative emissions building material.

“Wood should be a material of choice for building green.”3

James Wilson Ph.D., Oregon State University College of Forestry

Sustainability

“A sustainable forest management strategy aimed at maintaining or increasing forest carbon stocks, while producing an annual sustained yield of timber or energy from the forest, will generate the largest sustained (climate change) mitigation benefit,” stated the Nobel Prize-winning Intergovernmental Panel on Climate Change (Dovetail, 2015, p. 2). One common, but false, assumption related to this conclusion is that “sustainable forest management” requires lowering harvest rates. While limits are important to maintain balance, it is equally important to meet harvest quotas so that forests may reach their “carbon stock” potential.

Like any other organism, trees have a life cycle. Through much of that life cycle—which spans several decades—trees absorb carbon dioxide from the air. Yet, at the end of the life cycle, this absorption rate slows down and eventually stops. In other words, there is a maximum amount of carbon that a tree can absorb in its lifetime.

Sustainable forest management, as certified by bodies such as the Forest Stewardship Council and the Sustainable Forest Initiative requires a structured and careful approach to regular harvesting. With this approach, Lippke, Oneil, Harrison et al. (2011) assert that “Sustainably managed forests are essentially carbon neutral” (p. 327). According to the Society of American Foresters, “an estimated 25 percent U.S. private forestland is managed in accordance with one of the three major forest certification schemes (the Sustainable Forestry Initiative, the Forest Stewardship Council, and the American Tree Farm System), and conservation initiatives on private land… are becoming increasingly common” (Alvarez, 2007, p. iii).

And while deforestation is a valid concern, particularly for old-growth forests and ecosystems populated with species, it is entirely different from the regulated and legal timber industry in the United States, which has maintained a stable forest stock for the last 100 years despite an increase in demand and population. In fact, the Society of American Foresters reports that between 1953 and 2006, the standing inventory of both hardwood and softwood has increased by 49 percent, despite the total acreage of forestland remaining “essentially the same during the past century” (Alvarez, 2007, p. i).

One of the most important reasons for this stability is that deciduous trees, the source of hardwood timber, naturally replenish without requiring manual replanting. In fact, only about nine percent of our total forestland is planted. The “vast majority of forest land in the United States regenerates naturally,” allowing our forests and timberlands to stay healthy and vibrant with little need for outside intervention (U.S. Forest Service Office of Research and Development, 2016, p. 4-4).

Wood Buildings Benefit People

Another important consideration in the long-term viability of a shift towards wood-based building products is the positive or negative impacts on consumers. As more and more studies document the environmental advantages of building with wood, a new area of study, called evidence-based design, has gathered momentum in studying the effects of design on our psychological and physical needs. Though more research is forthcoming, beginning studies in evidence-based design have suggested that there is an “instinctive bond between humans and other living systems, [and] helps to describe the contribution of wood to an indoor building environment.” This bond is termed “biophilia” (National Geographic, 2017).

Studies indicate that this “instinctive bond” is more than just a mood booster: Being in spaces with natural and organic materials can have measurable and dramatic positive effects on our physical health. Because Americans spend an average of 90 percent of our time indoors, it makes sense that our physical and mental wellbeing can be so easily impacted by the types of spaces we work, learn, live, and sleep in (National Geographic, 2017).

“New research is also revealing that green buildings can actually be good for our health too.”4

Kelsey Nowakowski, National Geographic Society

Of the many aspects included in evidence-based design and green building design, one overlapping concern for developers is air quality and ventilation. While there are several options to improve airflow and quality of already existing buildings, the Environmental Protection Agency (2019) has one clear directive about how building materials can proactively prevent problems: “Choose building materials and furnishings that will keep indoor air pollution to a minimum…. Use exterior-grade pressed wood products made with phenol-formaldehyde resin in floors, cabinetry, and wall surfaces. Or, as an alternative, consider using solid wood products.”

Wood is also shown to directly impact human physiology in ways that reduce stress and worrying and promote creativity. Kotradyova, et al. (2019) shows that brain activity and behavioral expressions indicate “wood materials have considerable impact on human physiology…. The brain becomes calmer and less stressed” when in a wooden waiting room compared to the standard room (sec. 4).

Building with Wood Benefits the Bottom Line

While the cost of materials can fluctuate across markets, engineered and prefabricated wood products such as cross-laminated timber (CLT) offer significant savings on labor costs. Matthias Olt, Senior Associate at DLR Group, a design and engineering firm, reports that though the per-unit cost of CLT is still higher than steel equivalents, building with the material provided net savings as “the number of construction workers required on-site is cut in half” and it takes less time to put buildings together (De La Rosa, 2019).

Studying the Future | Oregon Forestry Center

To study the cost, health, and design effects of wood buildings in greater magnitude and over a larger period of time, the newly opened Oregon Forestry Center will serve as a “living lab” (Oregon State University, 2020).

In addition to the 381 built-in data collection devices as part of the “living lab,” the Oregon Forestry Center includes additional notable innovations. One is the choice of alder for the exterior of the building. This hardwood is not a common exterior choice. To protect the building from rot and discoloration, the wood was processed with a cutting-edge process called acetylation. This building is the first known use of acetylation being used on alder wood for exterior application and paves the way for future innovations in renewable building material.

Summary

With a better understanding of the positive impacts that exposure to wood products have on building tenants and the initiatives set in place to keep forests alive and renewable for decades to come, wood is the building material of the future.

Conclusion

This paper first examined the environmental effects of the timber industry as compared to the two other most common building material resources: concrete and steel. Using LCA tools and case studies, we compared greenhouse gas emissions during the lifecycle of the product, carbon storage, and energy efficiency. In each area, wood products were the clear choice for having a much lower GHG emission and energy use rate, as well as the active removal and storage of carbon dioxide from the atmosphere. For these reasons, and as numerous authorities have proclaimed, wood as a building material is the most environmentally responsible and preferential choice when available.

Next, the paper explored the sustainability of wood as a building material, as there is much social discourse around deforestation. After examining the growth-to-harvest ratio in the United States over the past century, as well as the overall acreage of timber, and lastly walking through the certification bodies that ensure proper sustainability measures are met, it is evident that even with an increase in demand, wood will be an available product and resource for decades to come.

Last, the paper examined the effects of wood on human physiology, as there has been an increase in studies on the topic, prompted by anecdotal and qualitative phenomenological expressions of preference for wood. These studies indicate a measurable and quantitative relationship between human physiology and wood: Wood environments lower stress, increase calm, lower heart rates and blood pressure, and increase creativity. Moreover, working in wood environments has been demonstrated to help prevent respiratory illnesses and absenteeism as well as increase overall productivity on a day-to-day basis.

With all facts thoroughly examined, we conclude that wood is a renewable and sustainable resource that provides the most beneficial effects to the environment as well as to the people who will inhabit and interact with it for decades to come.

References

Alvarez, M. (2007). The State of America’s Forests. The Society of American Foresters.

De La Rosa, S. (2019, June 5). Cross-laminated timber will save time, labor costs on local

commercial construction projects. Bisnow Seattle.

https://www.bisnow.com/seattle/news/construction-development/cross-laminated-timber-will-save-time-labor-costs-on-local-commercial-construction-projects-99301

Dovetail Partners, Inc. (2015). Building with wood: Proactive climate protection.

http://www.dovetailinc.org/report_pdfs/2015/building_with_wood.pdf

Environmental Protection Agency. (2018). Carbon storage in forests.

https://cfpub.epa.gov/roe/indicator.cfm?i=86

Environmental Protection Agency. (2019). The inside story: A guide to indoor air quality.

https://www.epa.gov/indoor-air-quality-iaq/inside-story-guide-indoor-air-quality

Halverson, M. (June 30, 2015). By nature, wood has nearly four times the thermal resistance of

steel or masonry. Building Design and Construction.

https://www.bdcnetwork.com/blog/which-more-efficient-wood-walls-or-steel-and-masonry-continuous-insulation

Perez-Garcia, J., Lippke, B., Briggs, D., Wilson, J., Bowyer, J., Meil, J. (2005). The environmental

performance of renewable building materials in the context of residential construction. Wood and Fiber Science, 37 (CORRIM Special Issue), pp. 3-17.

International Energy Agency. (2019). 2019 Global status report for buildings and construction:

Towards a zero-emission, efficient and resilient buildings and constructions sector. United Nations Environment Programme.

https://www.unenvironment.org/resources/publication/2019-global-status-report-buildings-and-construction-sector

Johnston, C.M.T., & Radeloff, V.C. (2019). Global mitigation potential of carbon stored in harvested wood products. Proceedings of the National Academy of Sciences of the United States of America, 116(29), 14526-14531.

https://doi.org/10.1073/pnas.1904231116

Kotradyova, V., Varinsky, E., Kalinakova, B., Petro, D., Jansakova, K., Boles, M., & Svobodova, H. (2019). Wood and its impact on humans and environment quality in health care facilities. International Journal of Environmental Research and Public Health, 16(18),

3496. doi: 10.3390/ijerph16183496

Lippke, B., Oneil, E., Harrison, R., Skog, K., Gustavsson, L., & Sathre, R. (2011). Life cycle impacts of forest management and wood utilization on carbon mitigation: Knowns and unknowns. Carbon Management, 2(3), 303–333. DOI: 10.4155/cmt.11.24

Lippke, B., Puettmann, M., & Oneil, E. (2019). Effective uses of forest-derived products to reduce carbon emissions. Consortium for Research on Renewable Industrial Materials.

https://corrim.org/wp-content/uploads/2020/01/Forest-Derived-Products-to-Reduce-Carbon-Emissions.pdf

Lippke, B., Wilson, J., Meil, J., & Taylor, A. (2010). Characterizing the importance of carbon stored in wood products. Wood and Fiber Science, 42(CORRIM Special Issue), pp. 5–14.

https://wfs.swst.org/index.php/wfs/article/view/1339

National Geographic. (2017). Green buildings could save our cities.

https://www.nationalgeographic.com/environment/urban-expeditions/green-buildings/benefits-of-green-buildings-human-health-economics-environment/

Oliver, R. (2017). Telling the whole story: The environmental life cycle of American hardwoods. American Hardwood Export Council.

https://www.dropbox.com/s/ssni8jy8a4o3jbf/Telling%20the%20whole%20story.pdf?dl=0

Oregon State University. (2020). Oregon forest science complex.

https://www.forestry.oregonstate.edu/ofsc/

Tahan, N. (2014, October 2). Energy efficiency and building with wood. Construction Specifier.

https://www.constructionspecifier.com/energy-efficiency-and-building-with-wood/

Ten Million Trees. (2018). All about trees. http://www.tenmilliontrees.org/trees/

University of Wisconsin-Madison. (2019). Wood products mitigate less than one percent of global carbon emissions. ScienceDaily.

https://www.sciencedaily.com/releases/2019/07/190701163837.htm

U.S. Forest Service Office of Research and Development. (2016). Future of America’s Forests and Rangelands.

https://www.fs.usda.gov/sites/default/files/fs_media/fs_document/5082_rpa2015.pdf

U.S. Forest Service Office of Sustainability & Climate. (n.d.). Forest Carbon FAQs.

https://www.fs.usda.gov/sites/default/files/Forest-Carbon-FAQs.pdf

Wilson, J. (2006). Chapter seven: Using wood products to reduce global warming. In Forests, Carbon and Climate Change: A Synthesis of Science Findings. Oregon Forest Resources

Institute, pp. 117-131.

Woodworks. (2011). Wood and carbon footprint. In Wood Design and Building Series.

https://www.woodworks.org/wp-content/uploads/Carbon-Footprint.pdf

Woodworks. (2012). Wood and green building: Wood design & building series.

https://www.woodworks.org/wp-content/uploads/2012/02/is-green-bldg.pdf

Join Our Mailing List

Stay up to date with the latest news in the hardwood industry.